Diesel-Shop for the K&AW - the Family-Line

For the next module on the Lotzburgh site a store for our short line railroad, the K&AW Line, The Family-Line is planned. Under the button Building Instructions you will find the vehicles ready made by Andy for this line so far. Now he has started the construction of a diesel shop.

Under the button building instructions you will find the construction of the turntable.

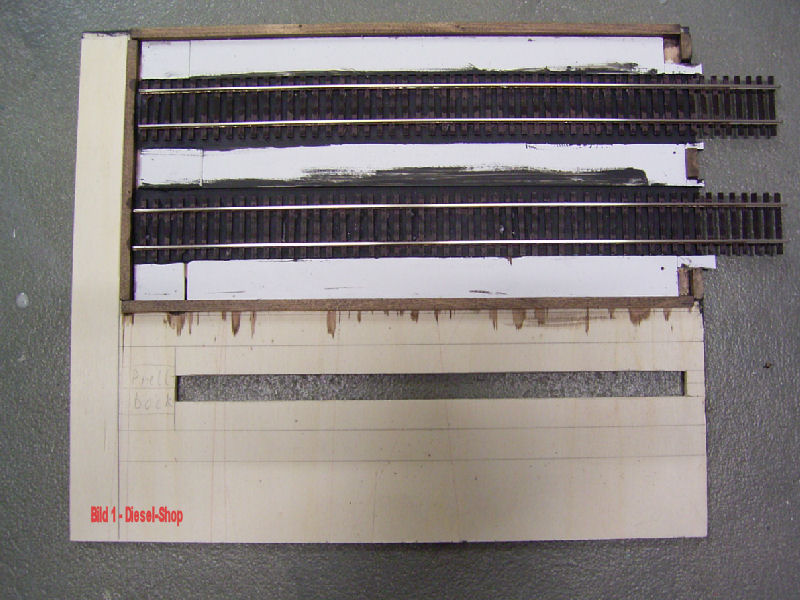

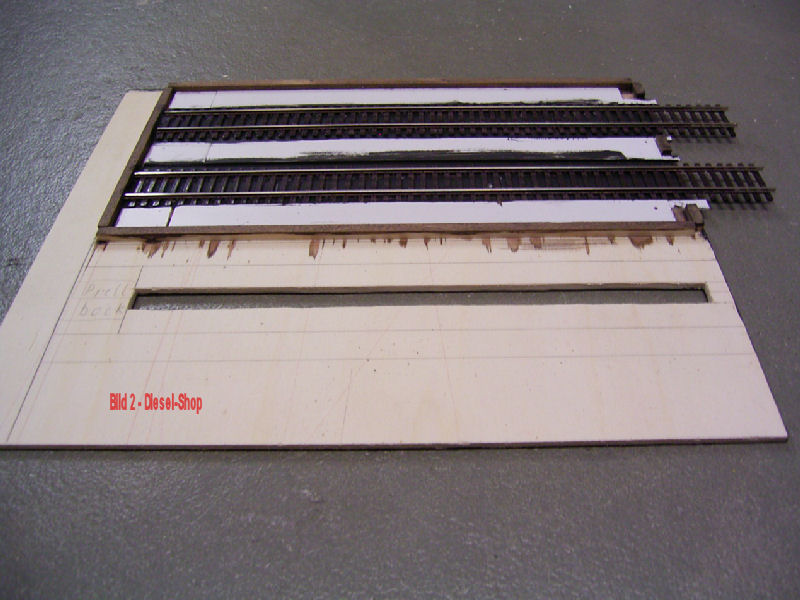

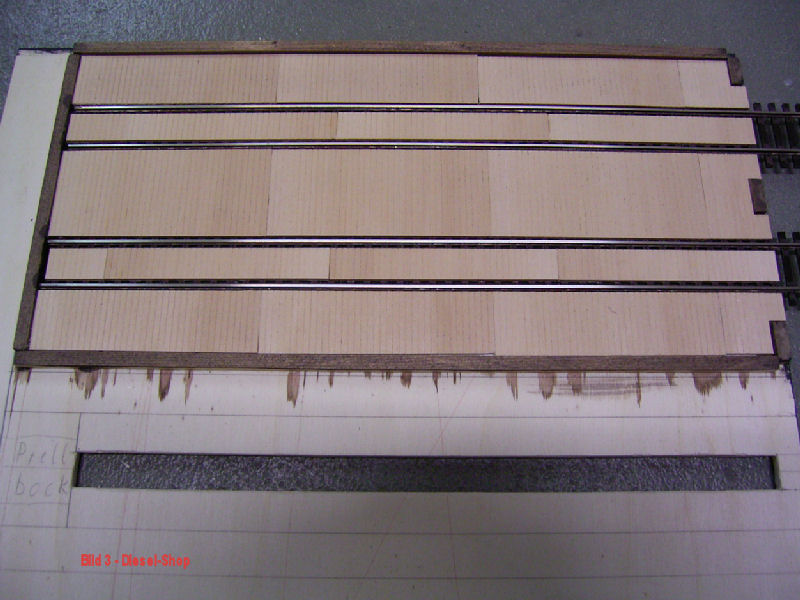

Fig. 1 und 2 - The base plate is made of 4mm plywood so that we have the height of our cork bedding. On it lie 2 tracks for the storage bays in the shed. The shed surface is bordered with 5x5mm wooden strips.

Fig. 3 und 4 - The gaps next to the tracks were filled with 2mm thick plastic boards to come to the height of the sleepers. The entire shed floor was then covered with wooden boards, also between the rails, to create a continuous floor surface.

Fig. 3 und 4 - The gaps next to the tracks were filled with 2mm thick plastic boards to come to the height of the sleepers. The entire shed floor was then covered with wooden boards, also between the rails, to create a continuous floor surface.

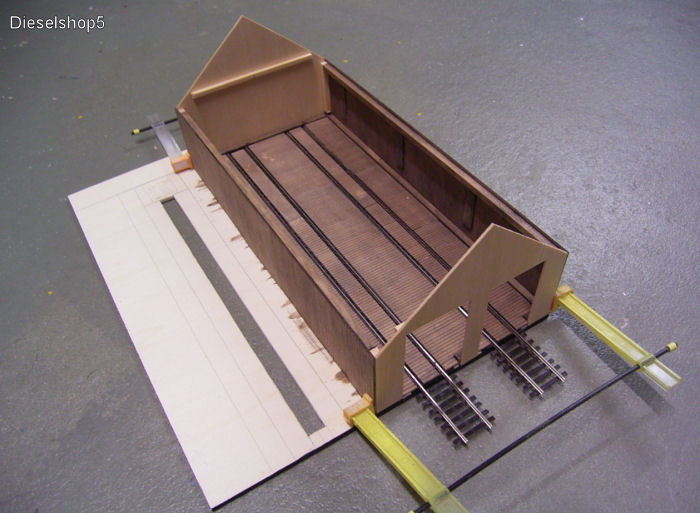

Subsequently, the entire floor was treated 2 times with wood stain "Oak Rustic".

In front of the shed, a hole was cut out that will later accommodate an inspection pit. To the left and right of the track are still catwalks to be able to better maintain the locomotives from the outside.

The whole thing then receives a protective roof for bad weather.

Unfortunately, the side walls for the shed will have to wait a little longer, as Artservice does not have the matching wooden boards in stock at the moment.

Fig. 5 - Hm, promised was a small shed..for RS 2 or so. Is the debris in the size of an RS 2??? Now I (Bernd) have to watch out, that there is not sometime a Big-Boy fits in. But, great job!

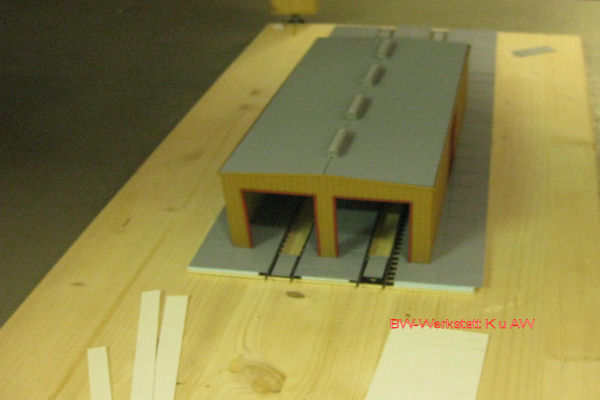

Fig. 6 - The wooden walls are in place. The sides are already covered with board veneers.

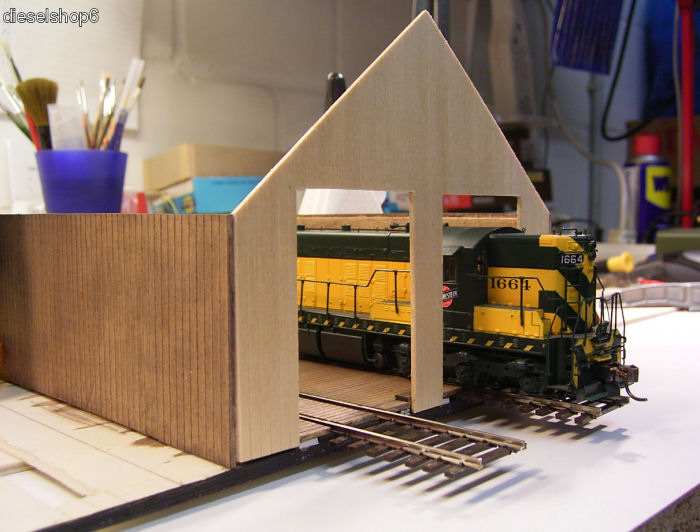

Fig. 7- The thick diesel fits through the gate. Wooden gates are still used here. Andy has already procured the hinges from an American small-series manufacturer.

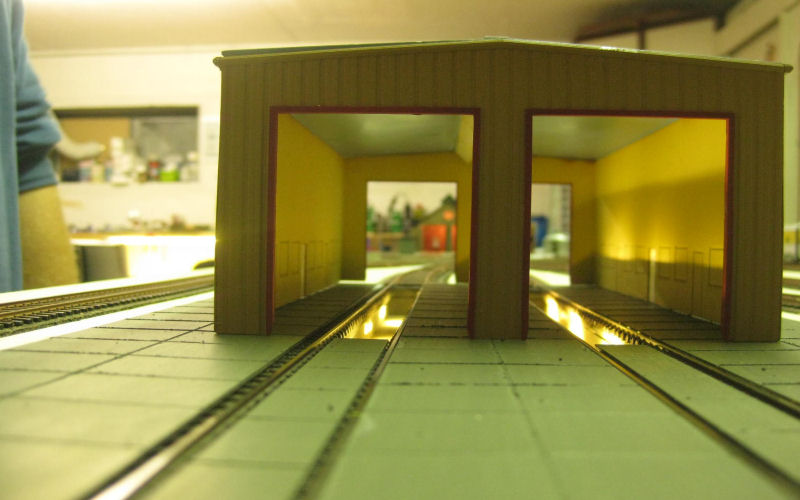

Fig. 8 - The windows are incorporated. The roof cannot yet be finished because another American small-batch manufacturer has not yet delivered the roof vents. The track in front of the shed gets an investigation pit and working platforms at the height of the locomotive turnarounds.

Fig. 9 - Andy finished the working platform on the side of the shed. A lot of work, but now really worth it. Cutting and painting all the parts alone is a huge effort.

Fig. 10 - Now the first diesel locomotive of the K&AW can be handled.

The roofs! The roof fans ordered by Andy are not available! Ordered for 6 months. Andy will now manufacture them himself.

Fig. 11 - Here you can see beautifully the construction of the stage. We have deliberately dispensed with concrete floors, etc.. The sand mixture is enough.

Fig. 12 - A view into the examination pit.

Fig. 13 - as already mentioned at Fig. 10, roof ventilators not available. So Andy made some out of wood himself. Despite the somewhat blurry picture, looks good. Now the shed doors have to be attached. Andy had already procured mini hinges from the USA. Absolute loupe work! Now the treatment track might get a protective roof.

Fig. 13 - as already mentioned at Fig. 10, roof ventilators not available. So Andy made some out of wood himself. Despite the somewhat blurry picture, looks good. Now the shed doors have to be attached. Andy had already procured mini hinges from the USA. Absolute loupe work! Now the treatment track might get a protective roof.

Fig. 14 - The gates are installed inckl. the hinges. With this, the shed is ready. The next module on the Lotzburgh side will house it. The construction will start soon.

Fig. 15 - The workshop building is being built. Here the already painted shell. The building is from Pikestaff in baby blue color.

Fig. 15 - The workshop building is being built. Here the already painted shell. The building is from Pikestaff in baby blue color.

Fig. 16 - Once again from the side.

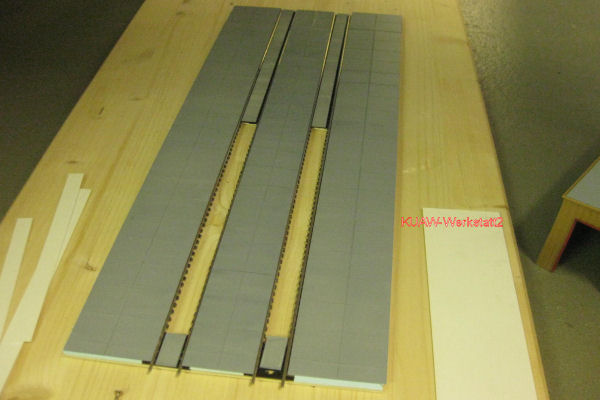

The bottom plate with dented rails. Already laid the base plates made of plastic with scored joints and the base color. Soil pits are installed in the areas left free between the rails.

Fig. 19 - The depot building is finished. Here, too, the lighting was installed. To prevent the crews from freezing, the building received a "cannon stove". The examination pit next to the depot building is also illuminated. The exterior lighting of the shop will follow in the last step.